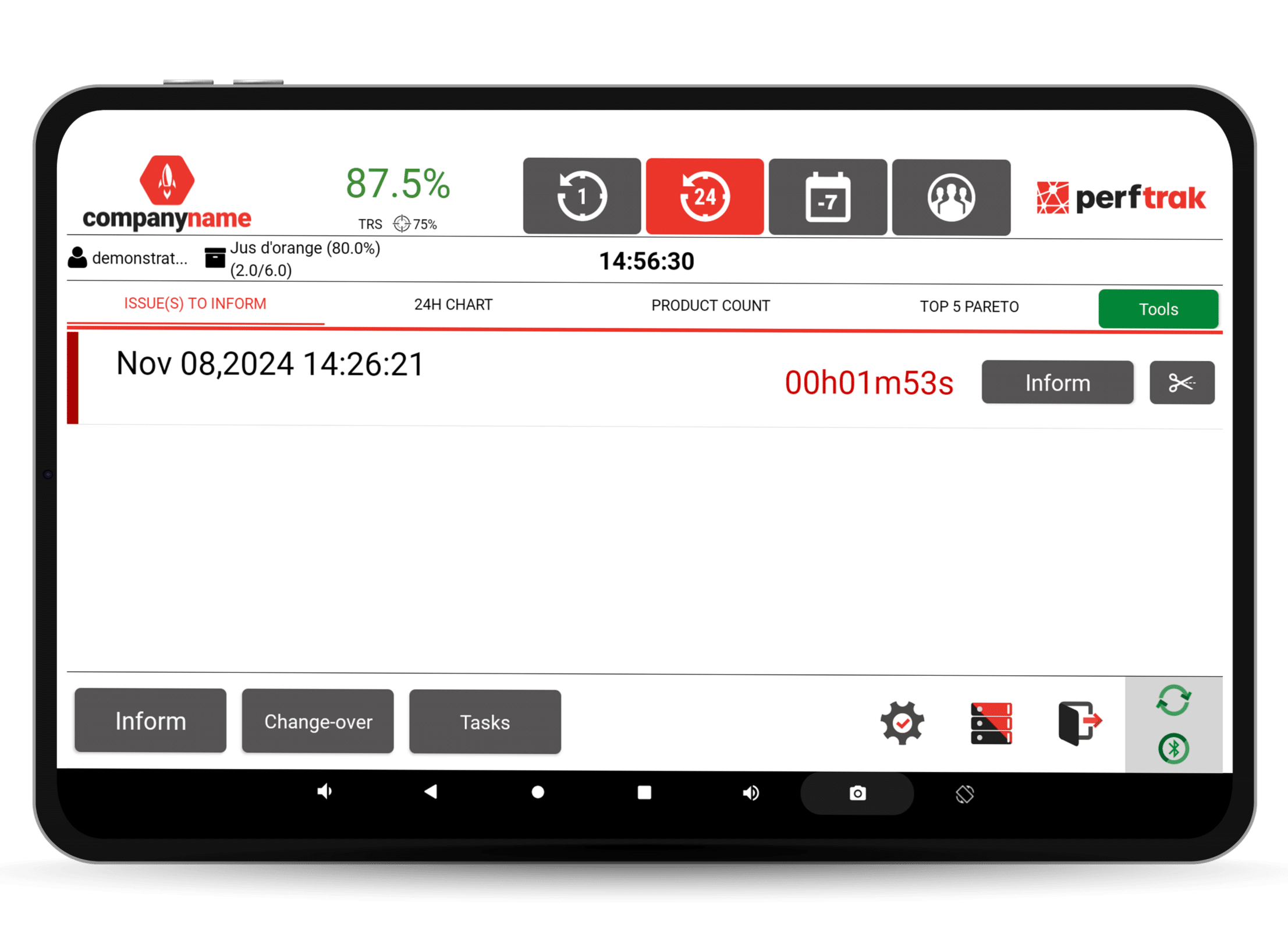

OEE Software to Track, Monitor, and Improve Productivity

Why manual OEE doesn't scale

Many OEE initiatives stall because data is hard to collect, slow to process, and not trusted by everyone.

- Data is collected manually on paper or spreadsheets

- Different plants calculate OEE in different ways

- Reports arrive too late for meaningful action

- Teams spend more time collecting data than improving performance

From data capture to daily improvements

Connect

Capture production and downtime data automatically from machine s, sensors, or existing systems.

Calculate

Compute availability, performance, and quality in real time using standardized rules.

Improve

Use dashboards, loss breakdowns, and trend analyses to drive st ructured improvement actions.

What manufacturers achieve with OEE software

Real Time OEE

See OEE per line, shift, product, or plant with live updates.

Remote Support

Experts can diagnose and advise without traveling, using live trends and alarms.

OEM / Machine Builders

Monitor machines installed at customer sites, of fering proactive service.

Historical Trends

Compare performance over time, across lines and plants, to verify the impact of improvement projects.

Turn OEE from a KPI into a daily habit

Operators

-

Understand targets vs. actual in real time

-

See the impact of downtime and speed losses during the shift

Remote Monitoring

-

Quickly identify chronic losses and validate improvements

-

Build structured PDCA cycles based on reliable data

Management

-

Share a single version of OEE across plants

-

Prioritize investments and projects based on proven impact

Where modern monitoring makes the difference

Share how you track OEE today and we’ll tailor a live demo with examples from factories similar to yours.