Industrial Monitoring Systems for Real Time & Remote Visibility

Monitor machines, lines, and plants in real time-from the control room or remotely-so you can react faster, reduce downtime, and improve performance.

If you don’t see problems in real time, you see them too late.

Without a proper monitoring system, you’re always discovering issues after they’ve already cost you time, money, or both.

- Operators only notice issues when machines stop completely

- Remote experts can’t help because they don’t see live process data

- Incident history is hard to reconstruct from manual notes

- Reports hide critical events behind static averages

Real time, remote, and automatically reported

Live Dashboards

See the status of every line, machine and area in one view, with cleacr color codes and KPIs.

Remote Monitoring

Secure web access for supervisors, engineers, and managers from any location, on desktop, tablet, or mobile.

Newsletter

Scheduled daily, weekly, and monthly reports delivered to inboxes so stakeholders are always informed.

Monitoring tailored to your teams

Monitor your plants securely from anywhere. Supervisors, experts, and managers can see live

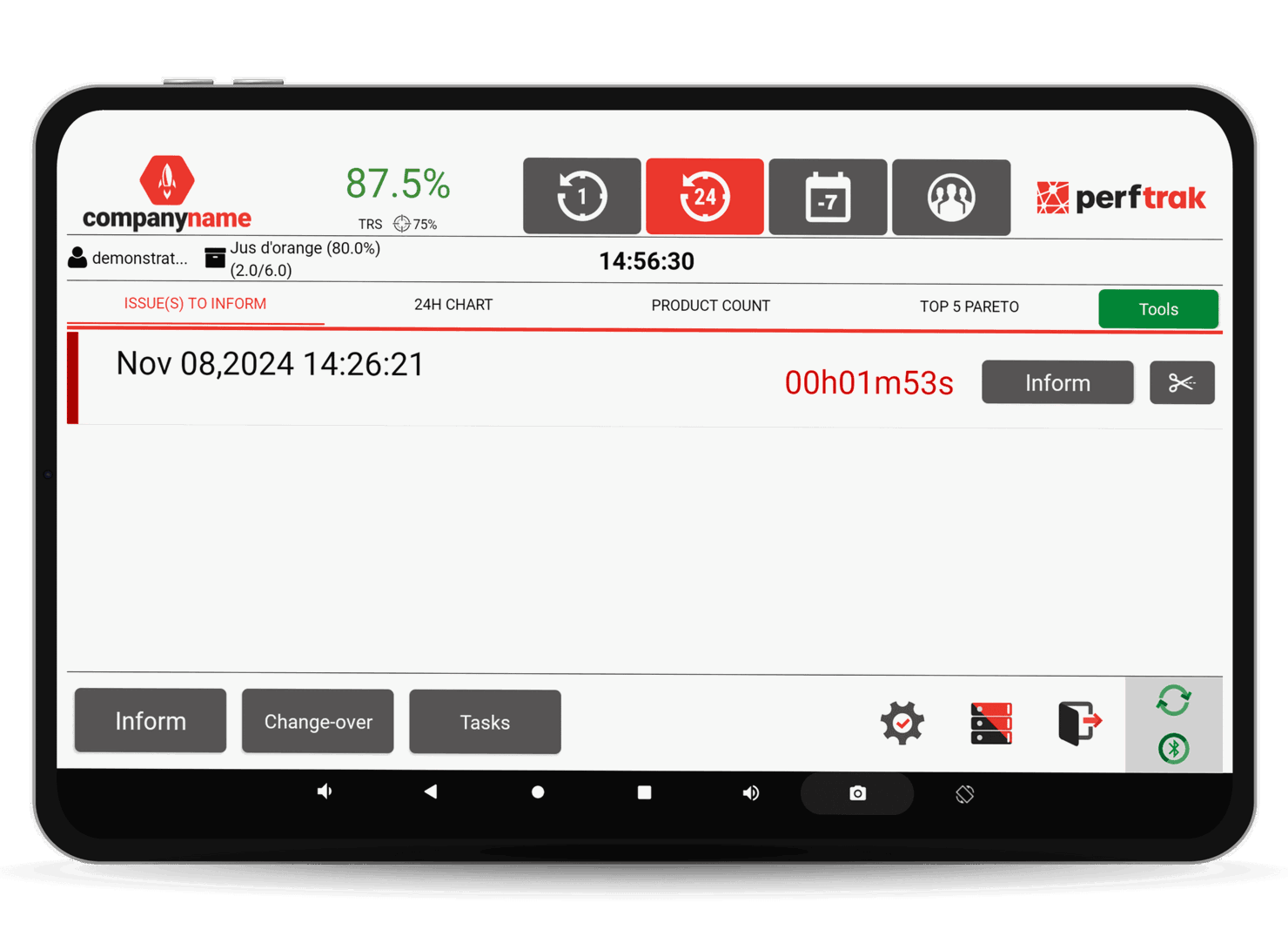

Operators

Simple, visual screens focused on the current line

Clear alarms and next actions

Easy way to log events or comments

Supervisors

Shift overview and alarm history

Downtime and speed trends by line

Tools to prioritize support and maintenance

Management

Shift overview and alarm history

Downtime and speed trends by line

Tools to prioritize support and maintenance

Real time, remote, and automatically reported

Monitoring Systems: Remote

Monitoring Systems: Remote Reporting

Where modern monitoring makes the difference

Multi Site Operations

Central teams oversee multiple plants in one view , spotting issues and supporting local teams.

Remote Support

Experts can diagnose and advise without traveling, using live trends and alarms.

OEM / Machine Builders

Monitor machines installed at customer sites, of fering proactive service.

Compliance & Safety

Make sure critical conditions are tracked and reported on time.

Where modern monitoring makes the difference

Discover the inspiring stories of our customers around the world who have transformed and optimised their operations thanks to our solutions.

Sylvain CLAUSSE

EIA Coordinator

Nutriset

The return on investment at Nutriset has been very rapid, because we have been able to eliminate a maximum number of what we call ‘irritants’, i.e. the little 3-4 second stoppages that sometimes occur fifty or a hundred times a shift.

Christophe PASQUET

Groupe PSA Stellantis

PerfTrak systems are already paying for themselves in terms of the time freed up for operators, who are now concentrating on value-added tasks rather than on collecting data and preparing reports.

Vincent PERRAULT

Head of Industrial Resources

Thanks to TeepTrak, we benefit from a standard, multi-site tool that enables us to monitor and analyze performance in the same way in heterogeneous environments, with significant cost savings.

IT’S UP TO YOU.

Unleash the power of your production.

See your lines live in a monitoring demo.

We’ll walk through a live monitoring dashboard, show how remote access works, and explore how to set up automated reports for your teams.