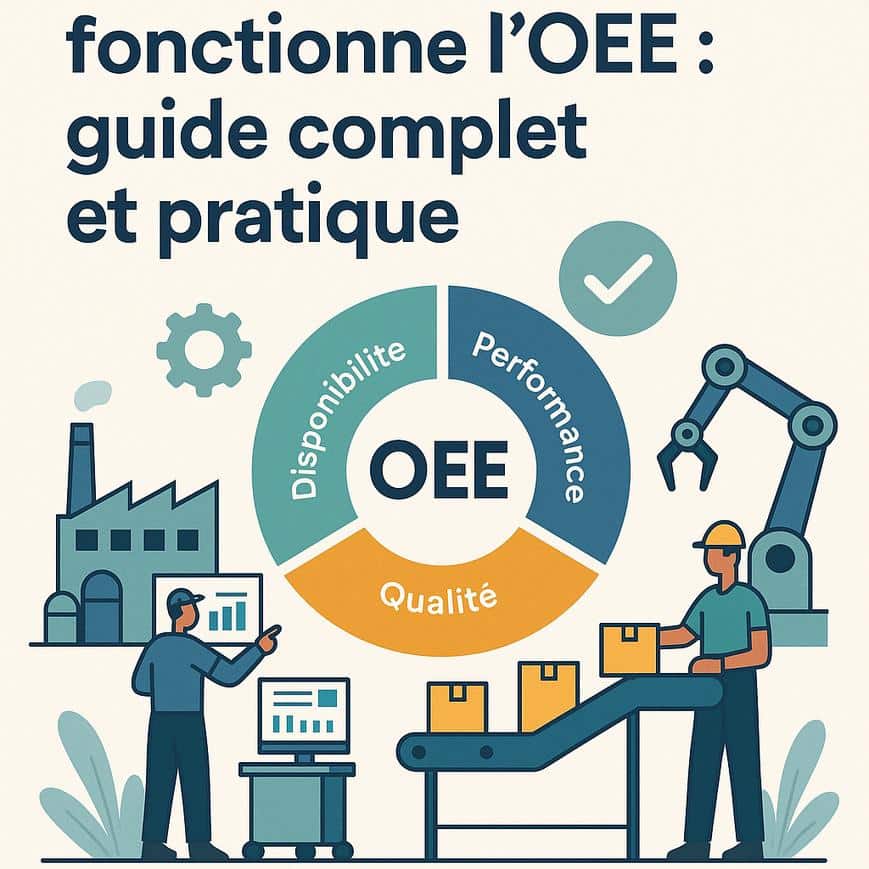

Overall Equipment Effectiveness (OEE) is a key indicator in the industrial sector, measuring plant productivity by integrating availability, performance and quality. Understanding how OEE works is crucial to optimizing the performance of your production lines and minimizing losses. In this context, this article explores the different aspects of OEE and how its use can transform industrial performance.

OEE is often seen as an excellent tool for identifying bottlenecks in production, by analyzing downtime, underperformance and quality defects. With TeepTrak, a

Imagine an automated production line in an assembly plant, where machines are subject to frequent stoppages due to unforeseen breakdowns. By implementing a solution like TeepTrak, in real time, you can detect these interruptions and analyze them to act quickly and avoid costly downtime. What’s more, a detailed analysis will enable you to understand the underlying reasons, such as lack of preventive maintenance.

Digitizing the shop floor, by integrating advanced monitoring and analysis tools such as TeepTrak, provides greater visibility over the entire operation, enhancing strategic decision-making. Adopting this approach not only helps to maintain a high level of productivity, but also promotes continuous improvement and overall competitiveness.

In conclusion, mastering the OEE concept and applying it effectively in the field can catalyze substantial gains in productivity and quality. Industrial managers are invited to use this information to launch digitization and OEE monitoring projects, reinforcing the development of an intelligent factory. To find out more, discover TeepTrak’s solutions for digitizing your production.

FAQ

Question 1: What is the OEE and why is it important?

OEE, or Overall Equipment Effectiveness, is a crucial industrial performance indicator for measuring production efficiency. It helps identify losses and improve overall productivity.

Question 2: How can the OEE improve productivity?

OEE helps to detect bottlenecks and inefficiencies, optimizing machine utilization and reducing downtime. This leads to improved productivity and higher yields.

Question 3: What tools help you track OEE in real time?

Solutions like those offered by TeepTrak enable real-time monitoring of OEE, providing detailed analyses to optimize production processes.

0 Comments