Unleash the power

of your production

Optimize every stage of your production with solutions designed to monitor and improve your performance while meeting your challenges.

All-in-one, turnkey industrial solutions

With their external integration, our all-in-one systems can be customized to your needs, are easy to deploy and ready to use in less than an hour in most production situations.

Immediately ready for use and compatible with 100% of your equipment, our solutions enable you to optimize your industrial processes quickly and efficiently.

DO THE MATH

Calculate your ROI

Instantly assess the return on investment (ROI) of our solutions with our dedicated tool.

Why calculate your ROI?

- Rapid assessment: Get an accurate and rapid estimate of the financial impact on your business.

- Maximise your investment: Identify opportunities to maximise benefits and improve efficiency.

- Strategic decisions: base your decisions on clear, concrete data for a better return on investment.

LEARN WITH OUR

TEEPTRAK Academy

Our Academy is your ultimate resource for mastering our solutions through comprehensive and accessible online training.

- Free and easy access: Are you a customer? Register for free at any time.

- Personalised learning: Progress at your own pace with lessons tailored to your needs.

- An intuitive way to learn: learn quickly thanks to intuitive teaching methods.

- Optimise your skills: Take full advantage of our solutions to improve your performance.

Monitor. Improve. Perform.

Drive your production with high-performance industrial solutions.

Thanks to our intuitive interface and advanced features, you can boost your performance in real time, quickly identify areas for improvement and optimise every stage of your process for remarkable results.

Real-time indicators

Compatible with 100% of machines

Improve your performance indicators

Quick installation (-1h)

Intuitive system

ROI in less than 6 months

Secure data

100% OPC UA compatible

Access operational performance data

in real time, wherever you are.

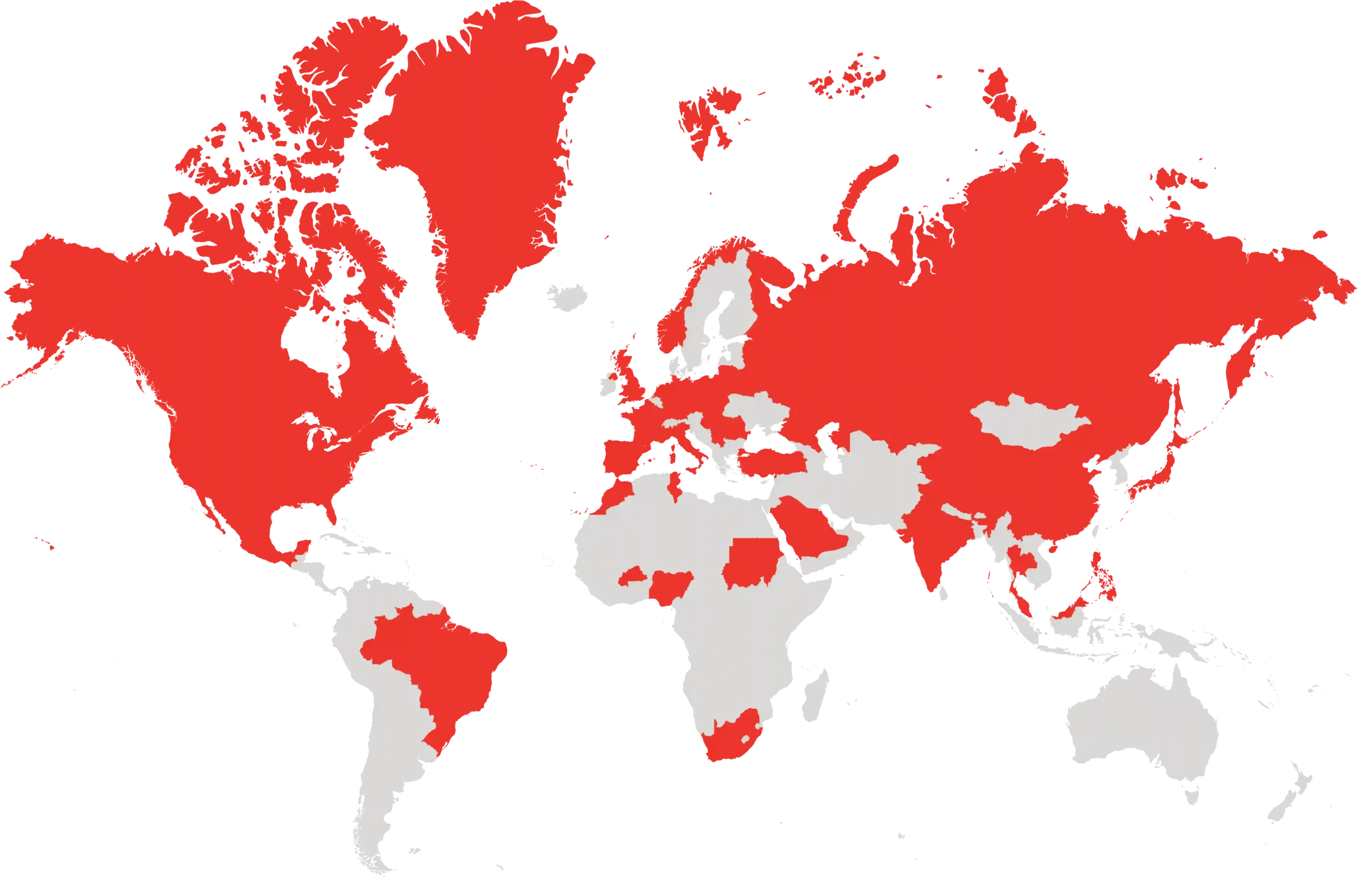

Key figures for TEEPTRAK

Data that reveals our impact in the industry.

Equipped plants

From small businesses to large groups

Customer groups

All convinced of the effectiveness of our solutions

Languages

So that everyone can use our solutions effectively

ROI in months

For most of our customers, ROI is calculated in weeks.

They trust us.

Discover the inspiring stories of our customers around the world who have transformed and optimised their operations

thanks to our solutions.

The return on investment at Nutriset has been very rapid, because we have been able to eliminate a maximum number of what we call ‘irritants’, i.e. the little 3-4 second stoppages that sometimes occur fifty or a hundred times a shift.

Sylvain CLAUSSE

EIA Coordinator Nutriset

Thanks to TeepTrak, we benefit from a standard, multi-site tool that enables us to monitor and analyze performance in the same way in heterogeneous environments, with significant cost savings.

Vincent PERRAULT

Head of Industrial Resources

Eolane Group

PerfTrak systems are already paying for themselves in terms of the time freed up for operators, who are now concentrating on value-added tasks rather than on collecting data and preparing reports.

Christophe PASQUET

Groupe PSA Stellantis

The PerfTrak solutions have enabled us to gain 10 to 15 TRS points, as well as precious time for the operators, who no longer have to fill in any documentation and can access the information themselves in real time.

Phillipe Devaux

Industrial Process Manager

Hutchinson Group

C.R.

Production & Maintenance

Manager

Miguel Waxin

President

APS Coating Group

IT’S UP TO YOU.