Libérez la puissance de votre production.

TEEPTRAK, leader européen du suivi de TRS

et de la performance industrielle,

propose des solutions innovantes pour accompagner les entreprises dans le suivi et l’amélioration de leurs performances.

Grâce à nos technologies avancées, nous vous aidons à identifier les leviers de productivité et à maximiser votre efficacité opérationnelle, tout en gardant le contrôle total de vos processus industriels.

Des solutions industrielles Tout-en-un, Clé en main

Grace à leur intégration externe, nos systèmes tout-en-un et modulables selon vos besoins, sont faciles à déployer et prêt à l’emploi en moins d’une heure dans la majorité des situations de production.

Immédiatement prêtes à l’emploi et compatibles avec 100% des équipements, nos solutions permettent une optimisation rapide et efficace de vos processus industriels.

FAITES LES COMPTES

Calculez votre ROI

Évaluez instantanément le retour sur investissement (ROI) de nos solutions avec notre outil dédié.

Pourquoi Calculer Votre ROI ?

- Évaluation rapide : Obtenez une estimation précise et rapide de l'impact financier pour votre entreprise.

- Maximisez votre investissement : Identifiez les opportunités pour maximiser les bénéfices et améliorer l’efficacité.

- Décisions stratégiques : Basez vos décisions sur des données claires et concrètes pour un meilleur retour sur investissement.

APPRENEZ AVEC NOTRE

Académie TEEPTRAK

Notre Académie est votre ressource ultime pour maîtriser nos solutions grâce à une formation en ligne complète et accessible.

- Accès gratuit et facile : Vous êtes client ? Inscrivez-vous gratuitement à tout moment.

- Apprentissage personnalisé : Progressez à votre rythme avec des cours adaptés à vos besoins.

- Une manière intuitive d'apprendre : Assimilez rapidement grâce à des méthodes d'enseignement intuitives.

- Optimisez vos compétences : Tirez pleinement parti de nos solutions pour améliorer vos performances.

Suivez. Améliorez. Performez.

Pilotez votre production avec des solutions expertes de la performance industrielle.

Grâce à notre interface intuitive et nos fonctionnalités avancées, boostez vos performances en temps réel, identifiez rapidement les axes d’amélioration, et optimisez chaque étape de votre processus pour des résultats remarquables.

Indicateurs en temps réel

Compatible avec 100% des machines

Améliorations de vos indicateurs de performance

Installation rapide (-1h)

Système intuitif

ROI en moins de 6 mois

Données sécurisées

100% compatible OPC UA

Accédez à des données de performance opérationnelle

en temps réel, où que vous soyez.

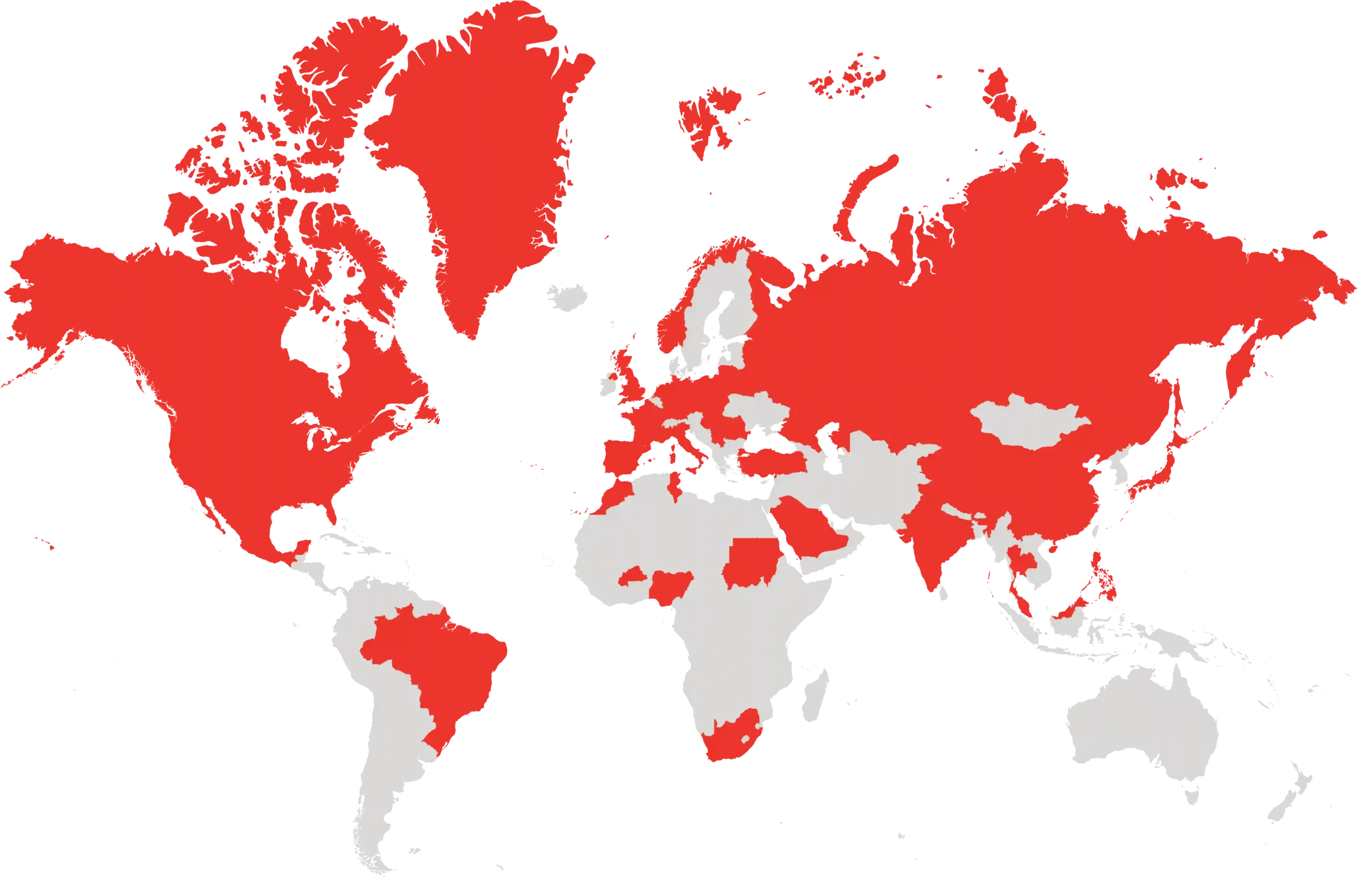

Chiffres clés de TEEPTRAK

Des données révélatrices de notre impact dans l’industrie.

Usines équipées

De la petite entreprise aux grands groupes

Groupes clients

Tous convaincus de l’efficacité de nos solutions

Langues

Pour que chacun puisse utiliser nos solutions efficacement

ROI en mois

Pour la majorité de nos clients, le ROI se calcule en semaines

Ils ont confiance en nous.

Découvrez les témoignages inspirants de nos clients à travers le monde qui ont transformé et optimisé leurs opérations

grâce à nos solutions.

Le retour sur investissement chez Nutriset a été très rapide, car nous avons pu éliminer un maximum de ce qu’on appelle chez nous les « irritants » c’est à dire les petits arrêts de 3-4 secondes mais qui se produisent des fois une cinquantaine ou une centaine de fois par quart.

Sylvain CLAUSSE

Coordinateur EIA Nutriset

Grâce à TEEPTRAK nous bénéficions d’un outil standard et multi-sites nous permettant de suivre et d’analyser les performances de manière identique dans des environnements hétérogènes avec un gain économique important.

Vincent PERRAULT

Head of Industrial Resources

Groupe Eolane

Les systèmes PerfTrak sont déjà rentabilisés compte tenu du temps libéré pour les opérateurs, maintenant concentrés sur les tâches à valeur ajoutée plutot que sur la collecte des données et la préparation des rapports.

Christophe PASQUET

Groupe PSA Stellantis

Les solutions PerfTrak nous ont permis de gagner 10 à 15 points TRS mais aussi un temps précieux pour les opérateurs qui n’ont plus aucune documentation à renseigner et qui peuvent eux-mêmes accéder à l’information en temps réel.

Phillipe Devaux

Directeur Processus Industriel

Groupe Hutchinson

C.R.

Production & Maintenance

Manager

Miguel Waxin

Président

Groupe APS Coating

C’EST À VOUS.