the innovative solution for digitizing and optimising all your quality controls

QUALTRAK

Ensure quality at every stage of your process

QualTrak has been designed to digitize and optimize all your quality controls, this innovative solution transforms the way you manage and analyze your quality data.

With QualTrak, all your quality controls, whether automatic or manual, are fully digitized. This enables data to be centralized and simplified, making them easier to use. Recorded in real time, the data collected enables instant calculation of your performance indicators, giving you immediate visibility of the quality of your processes and products.

Thanks to its real-time monitoring, QualTrak ensures optimum responsiveness to any drift or non-compliance. This enables you to detect and correct quality deviations without delay, guaranteeing precise and timely interventions. This enhanced responsiveness translates into better control of your processes and continuous quality improvement.

Operating principle

QualTrak revolutionizes quality management by providing instant, real-time monitoring. It combines accurate counting of good and defective parts with operator information to provide an in-depth understanding of quality losses.

The system enables agile, adaptable analysis on any time scale, ensuring rapid reaction to emerging quality issues. The system’s flexibility is such that the degree of interaction with operators can be configured according to the specific needs of each manufacturing process.

To use QualTrak, all you have to do is provide data on the quality defects and references to be checked. The inspection can then be carried out automatically, using robots for example, or manually at dedicated workstations. Defects can be reported by various means, such as the tablet’s touch screen, a button, a foot pedal or a sensor.

Automated data acquisition and operator input of defect causes ensure accurate data collection. This data is available in real time on our platform, providing immediate and transparent visibility of the quality performance of your production process.

Functionalityㅤ

QualTrak offers a full range of powerful, intuitive features to optimize quality management within your company. Designed to meet the needs of modern industries, this application facilitates the control of your products and enables effective management of non-conformities.

Thanks to results historization, our solution keeps an accurate record of inspections, making it easy to monitor quality over time and analyze trends to identify recurring causes of non-conformity and apply corrective actions.

QualTrak also calculates quality performance indicators based on real-time data, providing a clear view of your processes and products. You can track metrics such as compliance rate and number of non-conformances per batch, helping you to make decisions for continuous quality improvement.

QualTrak makes it possible to account for and analyze rejects, a crucial operation for assessing the costs associated with non-quality, reducing losses and optimizing operational costs.

INTUITIVE

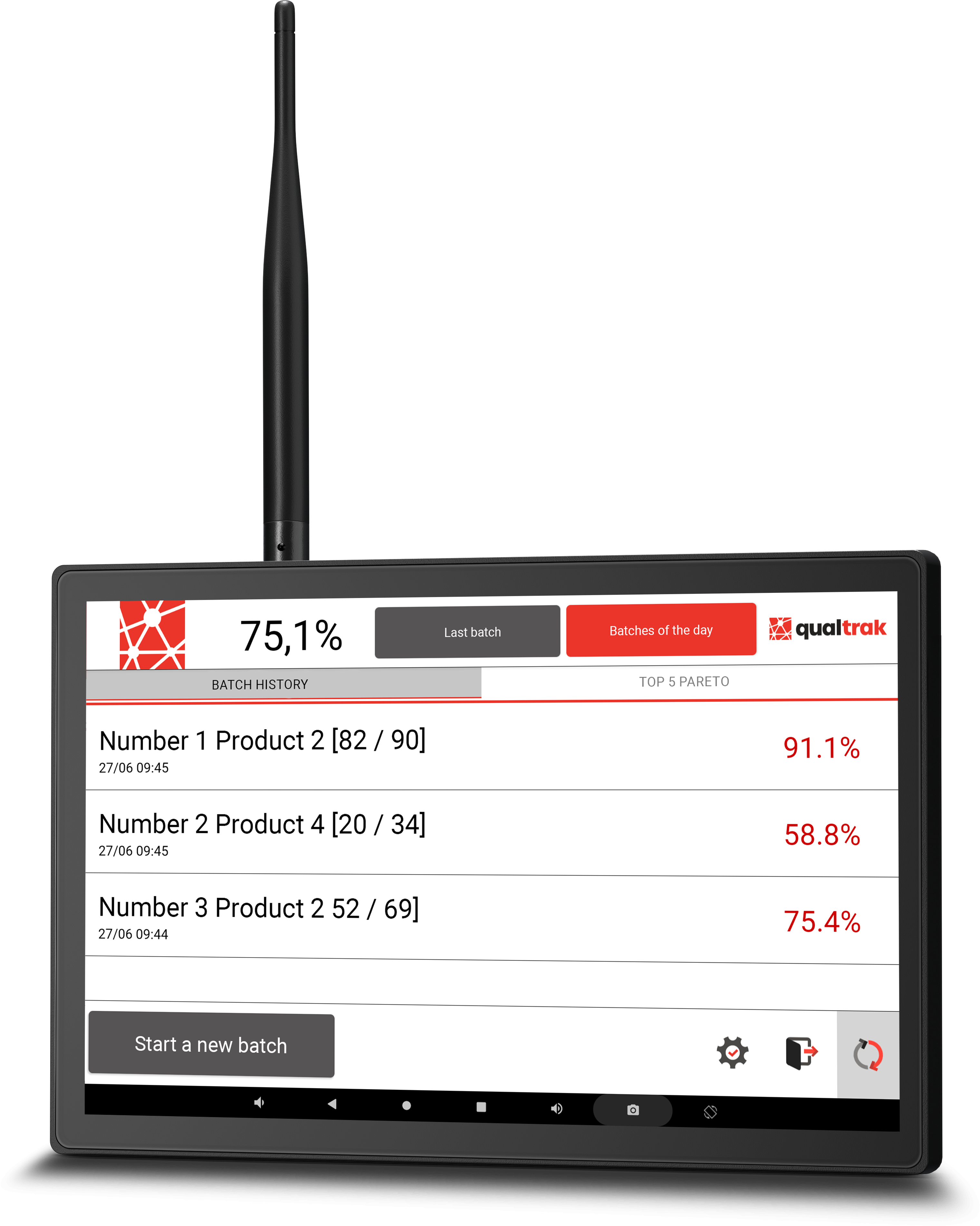

The tablet interface

An interface dedicated to real-time management and optimization of the quality of your products and production processes.

QualTrak’s tablet interface is specially designed to provide clear, instant visualization of quality parameters throughout your production process. Centralizing essential data in an intuitive application, it enables precise, real-time monitoring of your equipment’s performance.

This interface presents a comprehensive dashboard displaying all relevant metrics, such as compliance and rejection rates. Information is updated in real time, providing an immediate overview for easy interpretation and rapid decision-making.

QualTrak enables operators to monitor quality indicators, report faults by various means (touch screen, button, foot pedal, sensor) and access historical data for in-depth analysis. This flexible solution improves responsiveness to quality issues, optimises costs and reduces lead times by ensuring maximum efficiency and consistent quality in your operations.

Use this innovative, advanced solution to guarantee maximum efficiency and consistent quality in your industrial operations!

Installation stages

QualTrak is available in automatic, semi-automatic and manual versions to suit your needs. With or without an acquisition module.

In manual mode, the operator declares the number of bad parts and the reasons for them.

In semi-automatic mode, we detect an electrical signal at the arrival or exit of a part (good or bad exit).

In automatic mode, we detect the arrival of a part and one of the two outputs via an external sensor or an electrical signal.

1 • Install the tablet at the workstation

2 • Connect the module to a signal (optional)

3 • Enter your causes of non-quality

4 • Enter the part numbers of your products to be measured

QUALTRAK

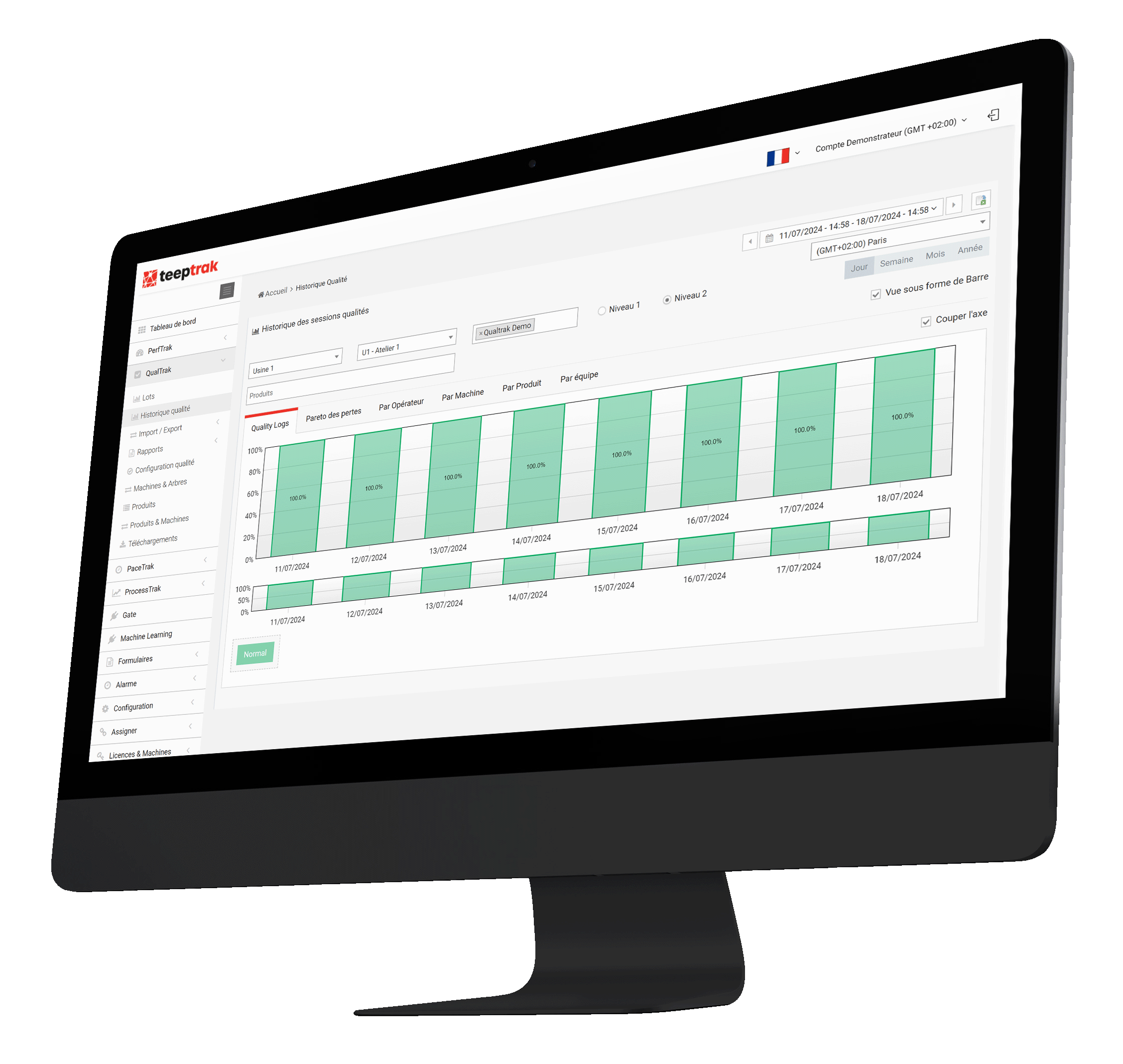

Supervision site

Data analysis

Take advantage of powerful analysis tools to examine data according to the period and scope of your choice, whether it’s a machine, a workshop, a plant or a team. Tailor your analyses to obtain relevant, detailed information.

Analysis tools

Access a full range of analysis tools, including quality performance indicators, real-time alarms, historical data, Pareto analysis of stoppages, automatic count reports, and scrap rate display. These features help you to monitor, evaluate and optimize your production processes on an ongoing basis.

Smartphone alarms

Receive instant alerts on your smartphone in the event of quality deviations or threshold shifts. Stay informed and responsive wherever you are, to minimise rejects and maximise production efficiency.

Access raw data and feed it into your BI

Extract raw data from your system to carry out in-depth customised analyses. This functionality allows you to manipulate and exploit information according to your specific needs, making it easier to take strategic decisions.

Use our APIs to feed your external dashboards and summarise the data.

Manual entry of values

Use interactive forms to view and monitor self-checks. Configure periodic statements according to the frequency, quantity and type of action required (e.g. temperature, weight). Ensure the compliance and quality of your operations through regular, rigorous checks.

Data analysis

Take advantage of powerful analysis tools to examine data by the time period and scope of your choice, whether it’s a machine, a workshop, a production line, a plant or a team. Tailor your analyses to obtain relevant, detailed information.

Analysis tools

Access a comprehensive range of analysis tools, including performance indicators, real-time alarms, historical data, Pareto analysis of downtime, automatic count reports and scrap rate display. These features help you to monitor, evaluate and optimise your production processes on an ongoing basis.

Access raw data and feed it into your BI

Extract raw data from your system to carry out in-depth customised analyses. This functionality allows you to manipulate and exploit information according to your specific needs, making it easier to take strategic decisions.

Use our APIs to feed your external dashboards and summarise the data.

Smartphone alarms

Receive instant alerts on your smartphone in the event of quality deviations or threshold shifts. Stay informed and responsive wherever you are, to minimise rejects and maximise production efficiency.

Manual entry of values

Use interactive forms to view and monitor self-checks. Configure periodic statements according to the frequency, quantity and type of action required (e.g. temperature, weight). Ensure the compliance and quality of your operations through regular, rigorous checks.