Industry’s good resolutions for 2021

Now that employees have brought the workshops back to life after the holidays, it’s time to make some good collective resolutions. Collective’ implies the entire workforce of a plant. The good resolutions will be ‘best-practices’. They depend on the sector of activity, but are applicable to all companies.

Good resolutions tailored to your business

According to the Comité des constructeurs français d’automobiles (CCFA) and its figures published on 1st As of 1 January 2021, the automotive market has shrunk by 25.5% in 2020. For the equipment manufacturers and other suppliers to these automotive giants, the main objective will be to cut costs. There are dozens of methods for making savings, the best of which are part of Lean Management. The most effective require creativity and innovation.

The use of Poka-Yoké (in assembly, for example, can prove invaluable. But what are they? Poka-Yokés are a means of preventing errors. They can be warning or operating. For example, a stop on a drill press is an operating Poka-Yoke because it prevents drilling too deep and makes human error impossible.

Detection devices on workstations limit the number of checks and favour parts that are right the first time. The aim is to protect against recurring or one-off faults caused by human error, by reducing the error rate to 0%. It is also a way of avoiding the risk of accidents. You can’t install Poka-Yokés in your workshop without first sending out a strong message. You need to show that it’s a solution, not a constraint, in order to motivate all your employees. Don’t forget that people on the shop floor often know how to improve things without realising it. You just have to keep listening.

Stay tuned, here’s a common-sense resolution. It may seem obvious to some, but given the constraints brought on by the health crisis, it can be difficult to maintain dialogue. Some employees have been teleworking for months. We’ve banked on their autonomy, and most of the time it’s been a success, as long as we stay tuned! For those on the shop floor, good ideas come from the field and an employee who is listened to is grateful, as well as sharing his or her knowledge. Here are three good reasons to keep listening to your employees.

In addition to listening, employee well-being also involves the right atmosphere. At the moment, it can be difficult for employees to keep smiling, with the slowdown in traffic, for example. The time available can be put to good use by organising seminars or get-togethers. Trying to see the glass as half full with your employees will help you to take advantage of difficult situations. However, you can’t force everyone to smile.

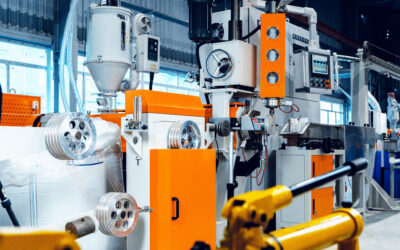

We’ve talked about the automotive industry, but not everyone is affected. In the pharmaceutical and paramedical industries, on the other hand, demand is outstripping supply. Lines are running at full capacity, and the end-of-year holidays were short. But the question remains: are the machines really working at full capacity? A good resolution would be to take an interest in the productivity of your equipment.

The best way to measure performance is through the TRS (Read our article on TRS). The Synthetic yield allows you to appreciate all the dimensions of a machine’s performance. Availability, reliability and product quality will hold no secrets for you. Once again, when deploying a tool of this kind, it’s essential to rely on your people in the field. Whether it’s finding your bottleneck or the least reliable workstation, you can count on your staff. They will be the main users. A successful first experience will enable you to implement a simpler changeover policy for your machinery.

In addition to being efficient, it is now essential to be informed in order to s’adapter. La demande évolue très rapidement, aussi vite que notre monde. Bien sûr, modifier des lignes de fabrication ou reformer le personnel demande du temps et de l’investissement, mais si vous répondez à une demande, cela peut vous permettre de sortir votre épingle du jeu. Si vous évoluez dans le bon sens, les résultats suivront. On parle ici de produit, mais l’adaptation est importante dans tous les domaines sans distinction, de la méthode de fabrication aux techniques de management.

Once you’ve added Poka-Yokés to your sensitive lines, or even in your offices; once you’ve listened to your teams and taken their opinions into account, while focusing on the performance of your equipment and adapting to the economic climate and changes in the world today; all the reasons will be there for you to have an excellent year in 2021.

The whole team at TeepTrak wishes you all the best for a prosperous and successful 2021.

0 Comments